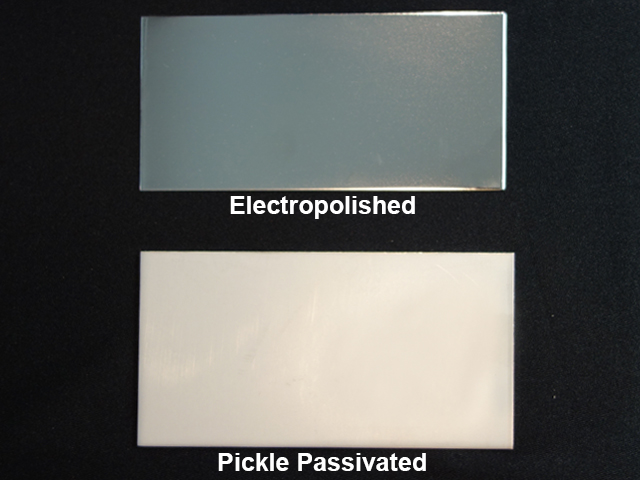

The main difference between pickle passivation and electropolishing is the appearance and RA (roughness average) of the stainless material. In the photo, an electropolished sample is shown above a pickle passivated sample. The pickle passivated sample has a white appearance, while the electropolished sample has a mirror-like, shiny finish.

Pickle Passivation is the immersion of metal in a pickling bath such as nitric-hydroflouric acid. The process removes metal such as impurities and heat marks from welds.

Electropolishing is an electro-chemical process that removes surface material from stainless steel. The process typically starts with an immersion of the component into a controlled bath of electrolyte that is charged with a DC power supply. Apache’s RA tests show improvements up to 50% smoother, depending on the material.

Do you have more questions like this one?

Check out the Contract Manufacturing FAQs page.