Large Tanks

Distillation Columns

Evaporators

Mix Tanks

Reactors

Sanitary Tanks

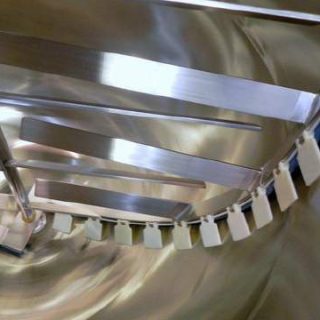

Distillation Columns

Apache commonly produces complex distillation column projects including add-ons for internal trays, insulation, cladding, ladders, and platforms as well as transport. Our engineers, technicians, and fabricators are experts in working with stainless, AL6XN, Hastelloy, and other high alloy materials.

Evaporators

Apache’s evaporators are fabricated to custom sizes and configurations for a variety of industries. Our expertise, facilities, and equipment have helped our customers get the highest quality single-pass and falling film evaporators in single or multiple quantities.

Mix Tanks

Apache has expertise with agitated vessels including standard props, full sweep, scraper blades, and high sheer rotating. We provide tanks built to customer specifications, with common aspects including sight glasses, lights, rupture discs, spray balls, and controls. Apache also has in-house capabilities for passivation and electropolishing stainless finishes often required for process tanks.

Reactors

Apache has a great deal of expertise in engineering and manufacturing heat exchangers and process reactors. All pieces of equipment are built to customer specifications, from a small lab reactor to a 160 ft. long industrial column reactor.

Our large tank engineers work closely with customers to determine:

- Structural design

- Heat transfer analysis

- Material finish requirements

- Agitation performance

Sanitary Tanks

Apache has best-in-class processes and expertise in compliance and surface finishes. ASME-certified sanitary tanks manufactured at Apache include:

- Cook tanks

- Mixing tanks

- Heat exchangers

- Process tanks

- Storage tanks

Our sanitary tanks are found in the food, beverage, pharmaceutical, biotechnology, water filtration, and health and beauty industries. We have also manufactured tanks and vessels for WFI (Water for Injection) and CIP (Clean-in-Place) processes.

FAQ – Large Vessels

In Apache’s Beaver Dam facility, we work with 300 grade stainless materials, predominantly 304/L and 316/L. We also work with high alloy materials such as AL6XN, duplex 2304, 2205 and 2507, Inconel and Hastelloy

Dimple jacket, half-pipe, conventional jacket, electrical heat tracing.

ASME F&D, F&D, Shallow F&D, Flat, Cone, Sloped, Hemi, Elliptical

We can fabricate Heads, anywhere from 30” (2’6”) to 192” (16’) in Diameter, with the thickness being 12 ga. to ¾” Stainless and up to 7/8” Carbon.

A wetted surface is a product contact surface or interior surface. It includes an area in nozzles up to the gaskets.

Use tri-clamp connections for sanitary and quick connection applications.

Depending on the application, we provide ANSI B16.5 150#, 300#, etc. RFWN, RFSO, and Lap Joint flanges, studding outlet (pad) flanges for standard ASME applications. For sanitary applications, we also provide tri-clamp ferrules, and tank bottom diaphragm valves such as ASEPCO, GEMU, PBM, NOVASEPTIC, etc.

Ball valves, diaphragm valves and gate valves. Some offer manual or pneumatic actuation options.

Mineral wool in various densities and foam glass. We can take a look at other insulation requirements that you may have.

Mill, 2B, No. 4, No. 4A, Bead Blast, Passivation, Pickle Passivation, and electropolishing

The weight limitation is dependent on the tank/vessel configuration, typically we want to keep the vessel below 70,000 lbs. We have built tanks weighing 250,000 lbs., but special consideration with outside riggers was required.

15 ft. diameter is the maximum typically.

Liquid Dye Penetrant testing, hydrostatic testing, spray ball Riboflavin testing, pharmaceutical drain testing, surface finish testing, PMI (Positive Material Identification), and radiography (at an additional cost).

Hydro, Riboflavin, dye penetrant, saline, drain ability, radiography, agitation run testing

- NB/ASME U Certificate for Beaver Dam, WI

- NB/ASME UM Certificate for Beaver Dam, WI

- CE Marking Permission for Beaver Dam, WI

- R Repair Certificate National Board of Boiler & Pressure Vessel Inspectors, Beaver Dam, WI

- SELO License for Beaver Dam, WI

ASME Code is generally required on tanks above 15 psig or vacuum applications.

A project engineer will coordinate communications, schedules and questions. There will also be a technical specialist that works on your project.

On larger projects, updates to the schedule are communicated upon drawing approval submission, then once per month, after project changes or per customer requirements.

We work with leading agitator manufacturers and we also have made custom agitators for special applications.